The wire rod mill in Liberty Ostrava has new shears. Modernization worth 40 million Czech crowns will save production costs and increase reliability and productivity of the wire rod mill

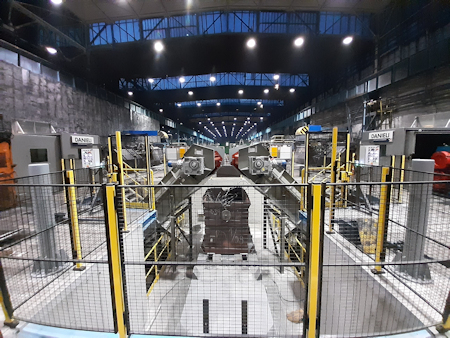

Ostrava 27 January 2020 – Higher reliability, reduction of maintenance costs and increase of productivity. These are the main benefits of the new shears for the wire rod mill. Shears, which are used for cutting the ends of wire before its final rolling and help to eliminate defects, have replaced the original facility from the 1990s. The shears were supplied by Italian company Danieli, the installation took place during the planned shutdown at the end of the year and now the shears are fully in operation.

“The planning, engineering, contracting, implementation and integration in an operating plant within one year is very satisfying,” said Miroslav Rojicek, head of Rolling mill projects in Liberty Ostrava.

The end shears are situated at the wire rod mill, which produces 5.5 - 14 mm diameter wire rod of billets of 1.2 tonne. The innovation is designed to conform to the parameters of the best available technique (BAT).

„The innovation has met all our expectations so far and in the future it will also be able to cut wire of higher diameters than we now manufacture. It will increase the rolling speed and thanks to that also the productivity of the rolling mill,” added Jiri Zboril head of the wire rod mill in Liberty Ostrava.

Liberty Ostrava is an integrated steel business with an annual production of c. 2 million tonnes of steel, which is mainly used in construction, machinery and oil & gas industries. The company is a domestic leader in the manufacture of road barriers and tubes. In addition to the Czech market, it supplies its products to more than 40 countries around the world. Together with its subsidiaries in Ostrava, the company has 6,150 employees. As a result of the above-standard greening, the company manufactures its products with a minimum possible environmental footprint. It is part of Liberty Steel, a global steel and mining business. Liberty Steel is part of the GFG Alliance, a global group of energy, mining, metals, engineering, logistics, and financial services businesses, headquartered in London, with a presence in around 30 countries worldwide. The Alliance has a global workforce of around 30,000 people and a turnover exceeding US$20 billion.